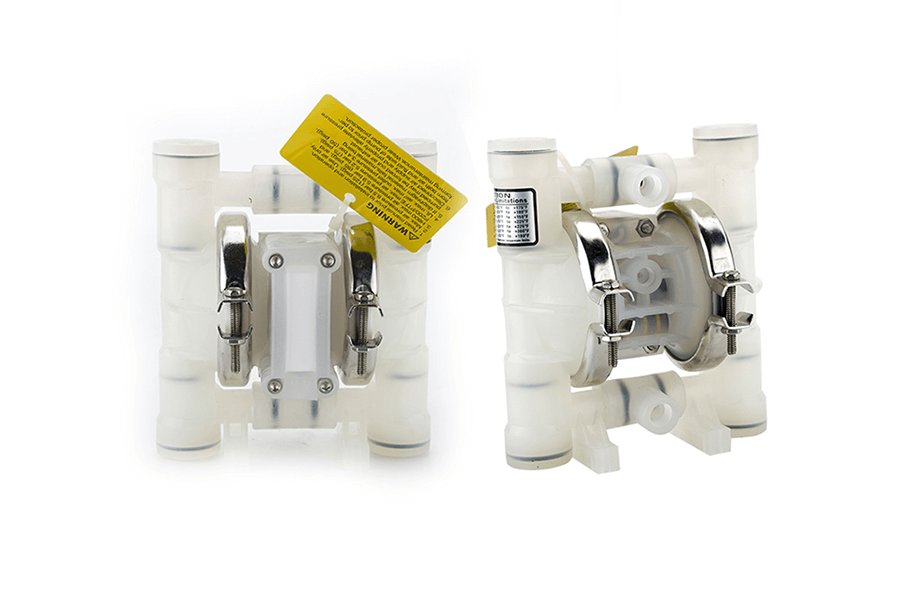

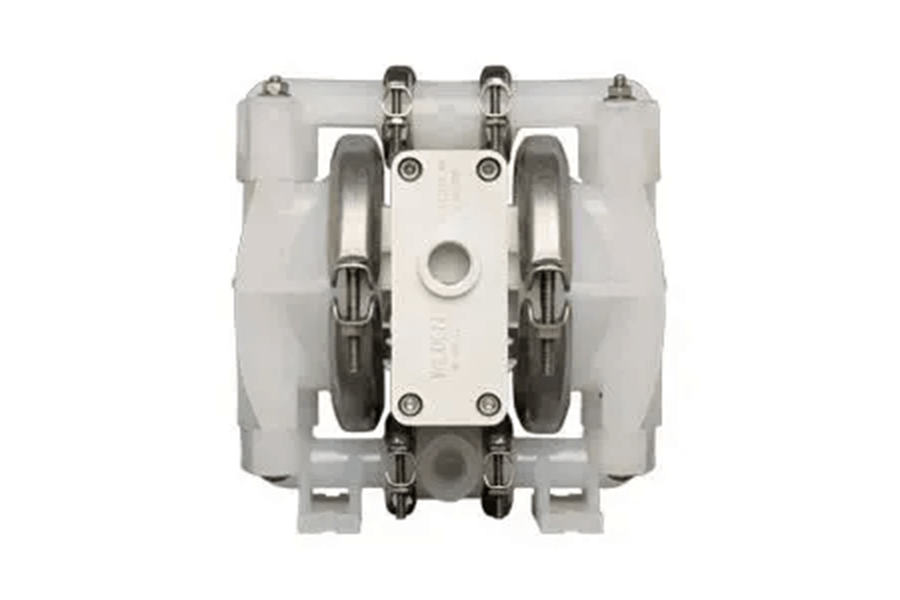

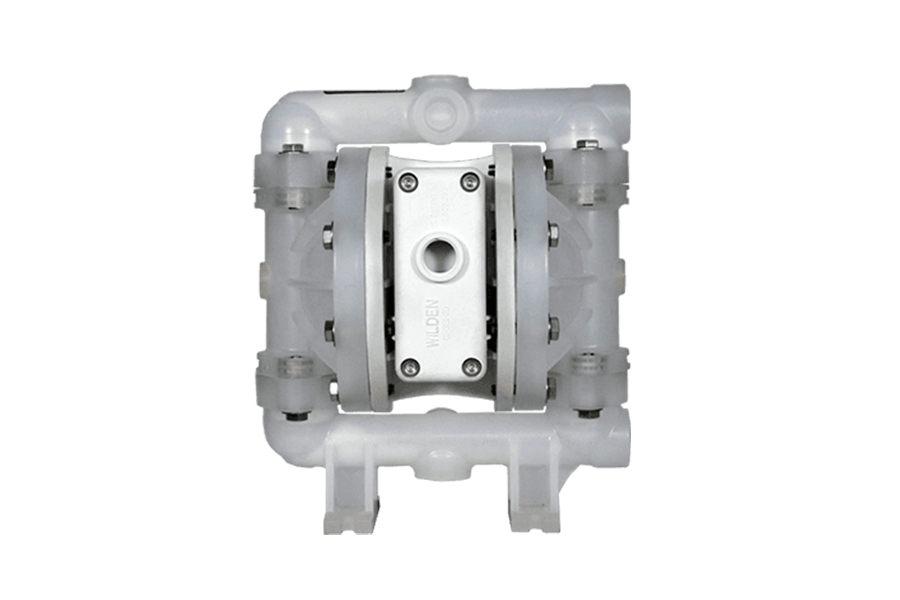

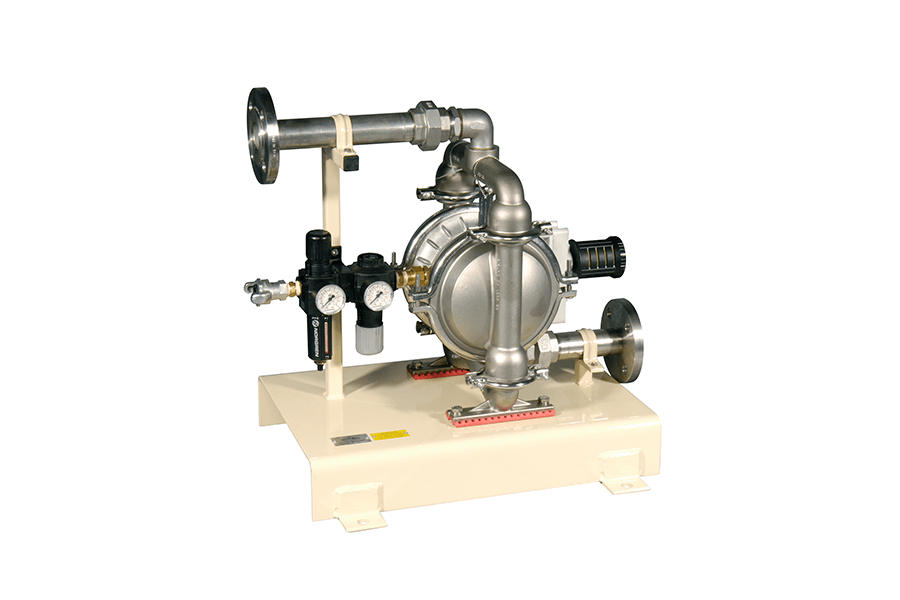

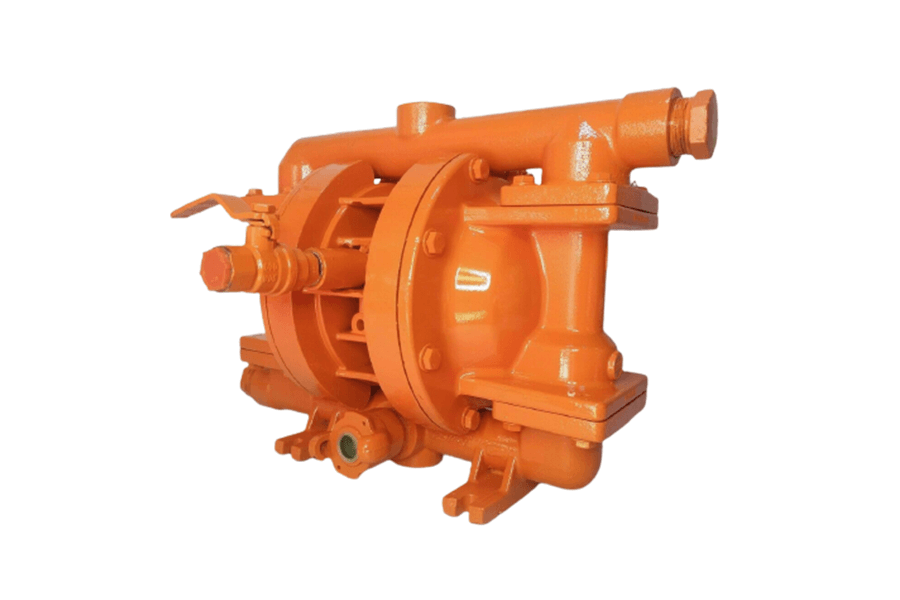

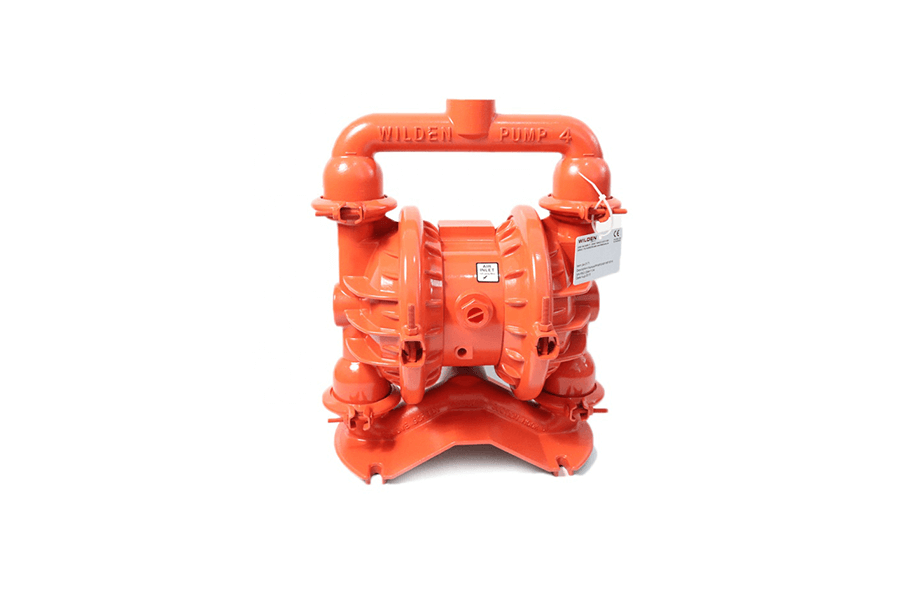

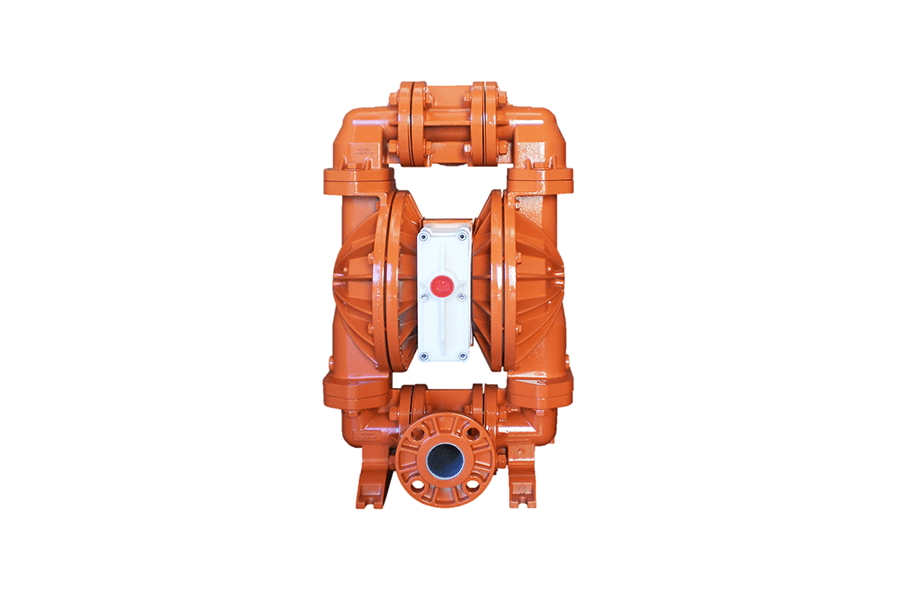

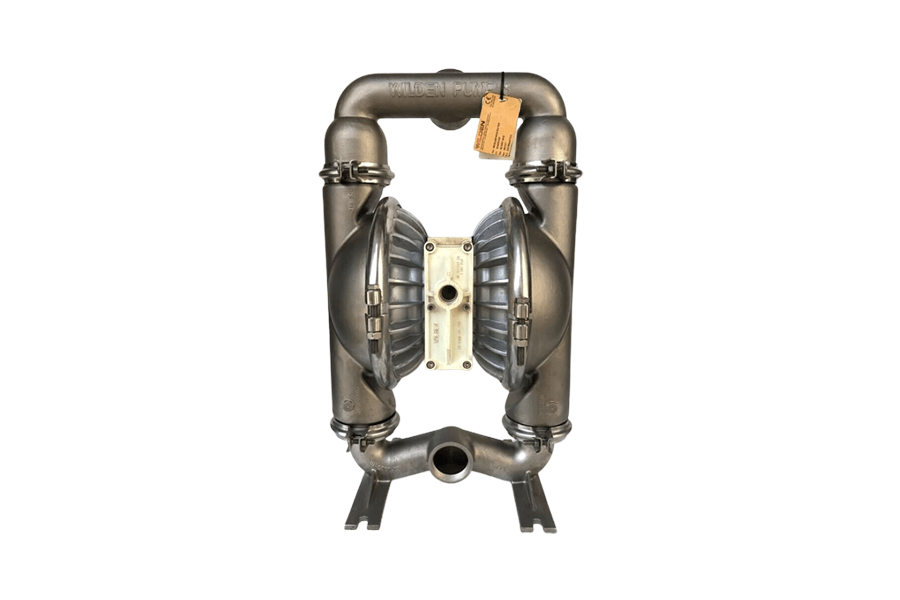

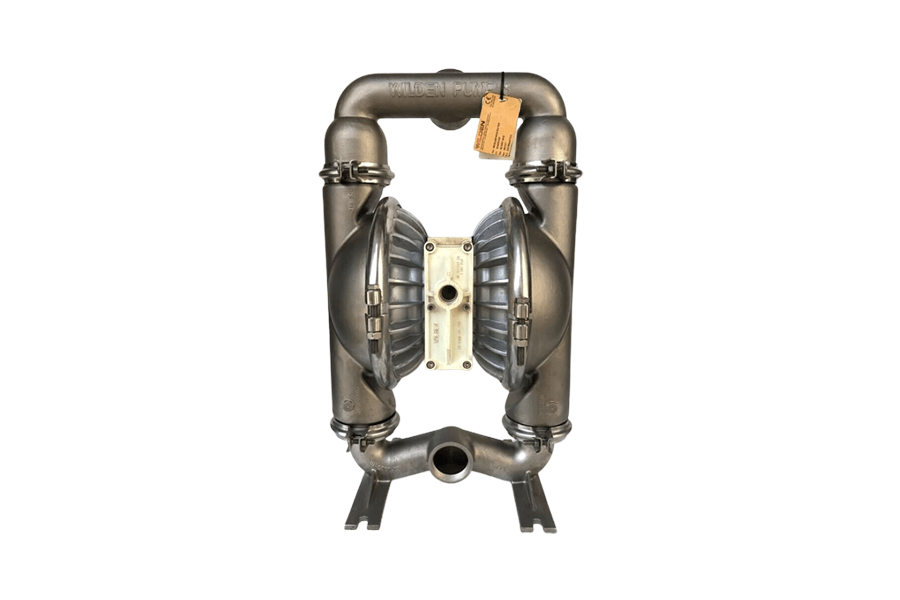

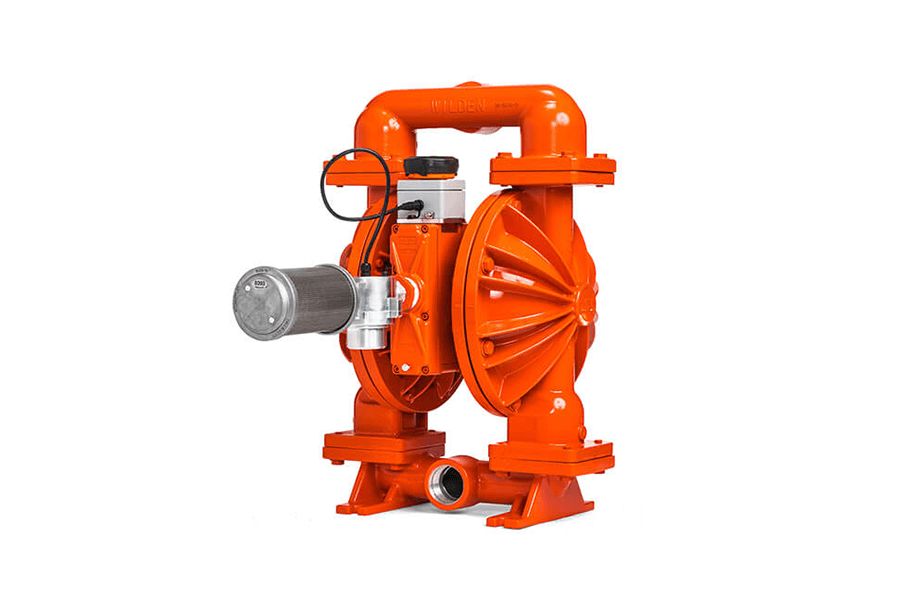

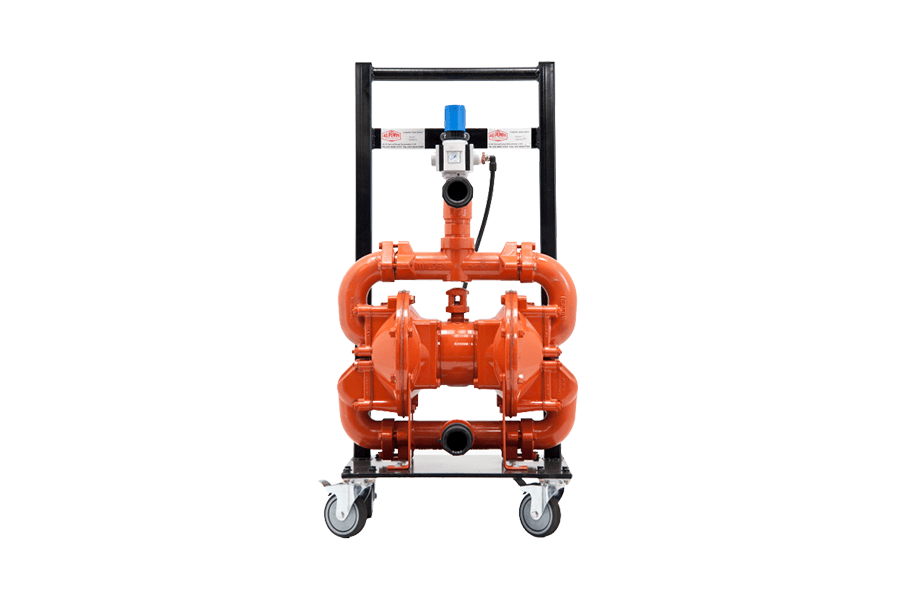

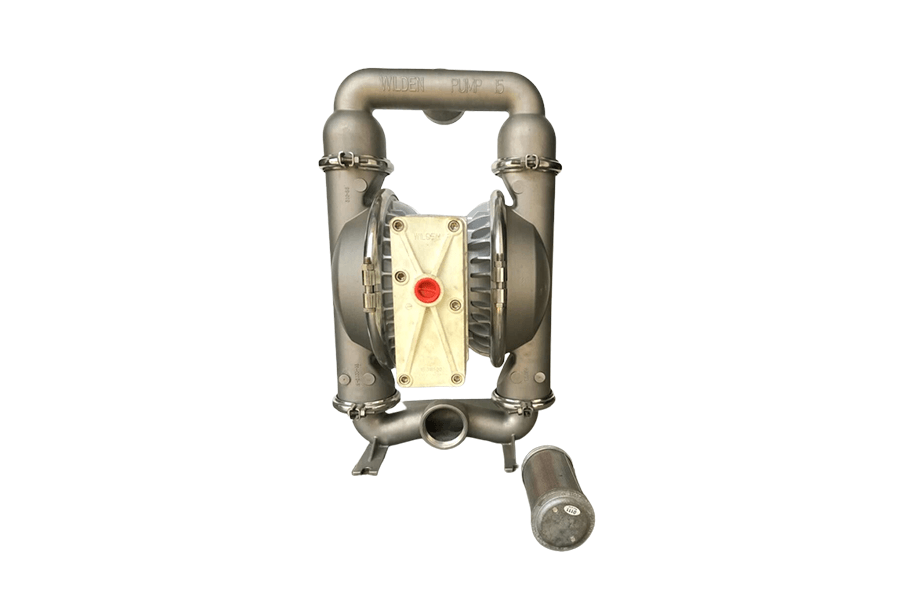

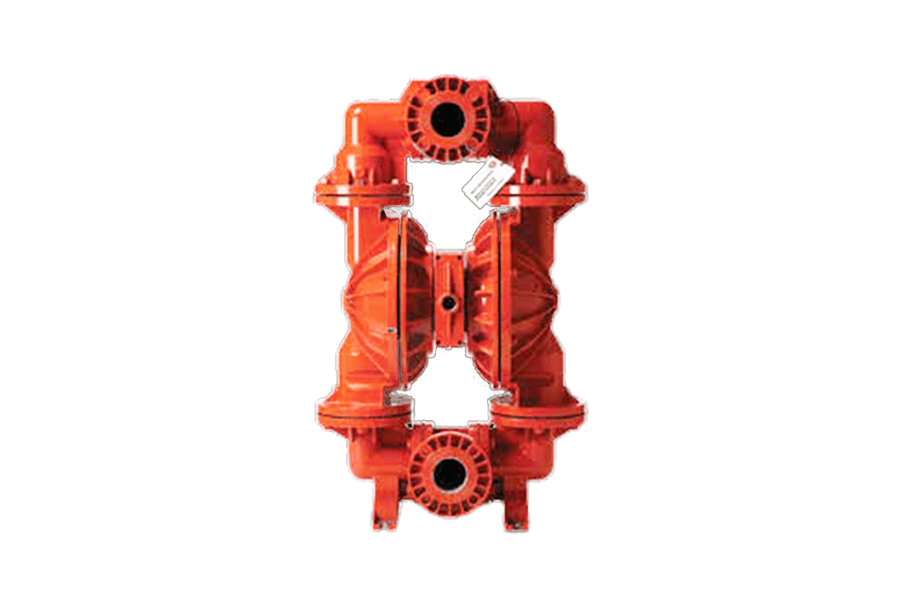

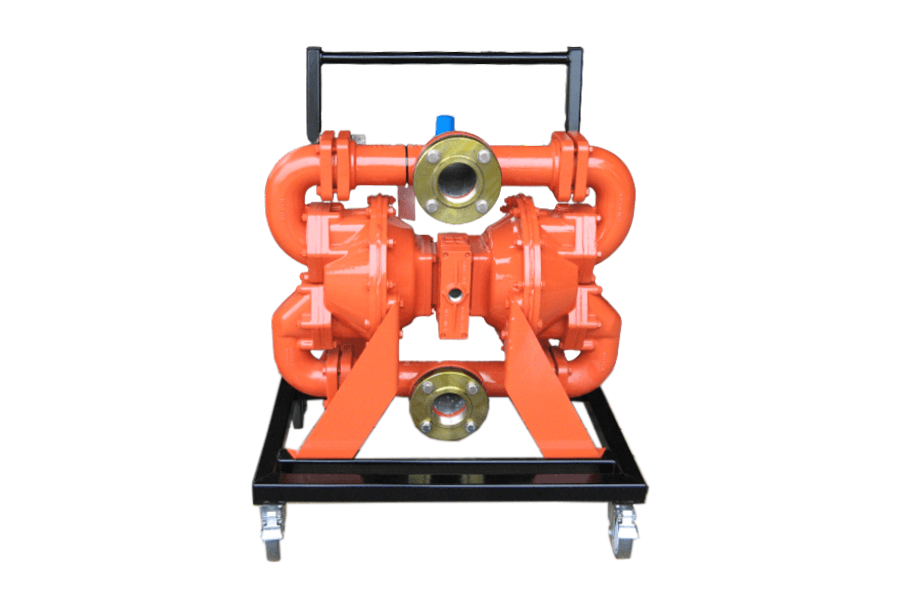

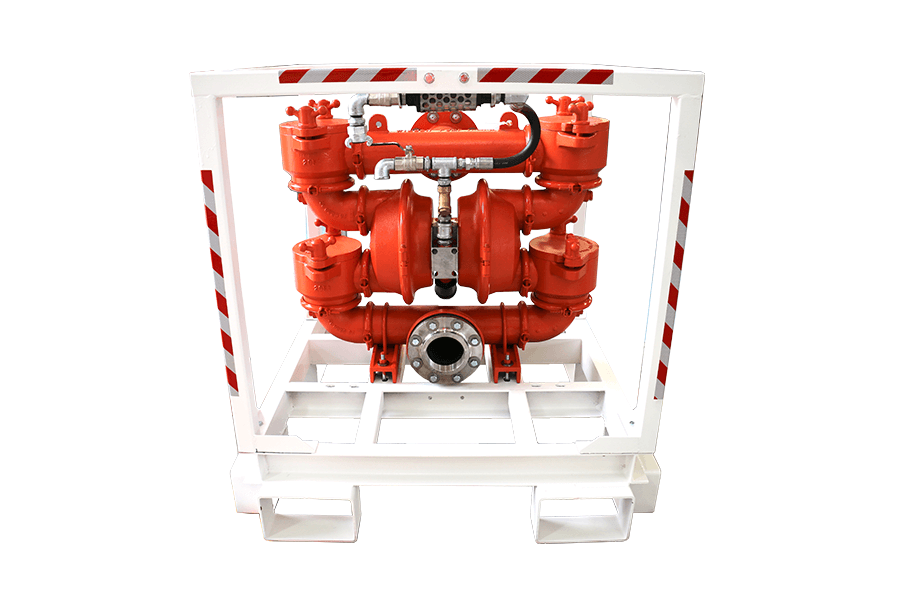

Wilden is a brand that specialises in the design and manufacture of

air-operated double diaphragm pumps. Since 1955, the company has never ceased improving its AOD technology to provide the best equipment to every industry across the globe. Each Wilden pump is engineered to deliver a wide range of flow rates and outlet pressure levels, for greater versatility. Meticulously designed pump configurations guarantee total pumped media containment, while optimized internal liquid paths reduce friction to maximize output and efficiency.